Robots as efficient tube bending machines

Robots have already been used for some time as efficient and flexible bending machines to process tubes. These systems are constantly developed and improved.

For the transfluid engineers this means first of all to make the software user-friendly. These bending systems from transfluid can take isometrics data and generate bending data without separate programming of the robot system.

transfluid has now designed the next step of its tube bending robots. The online connection to CAD systems reduces the set-up time a lot. Another important aspect is to simplify the software connection for more convenience for the customer.

The latest generation of machines can process isometrics data online. There are also positions stored in the control system, where the piece is picked up and dropped off. A complete new complex bending geometry can be programmed quickly, in max. 30 minutes. This including the set-up of the bending tools.

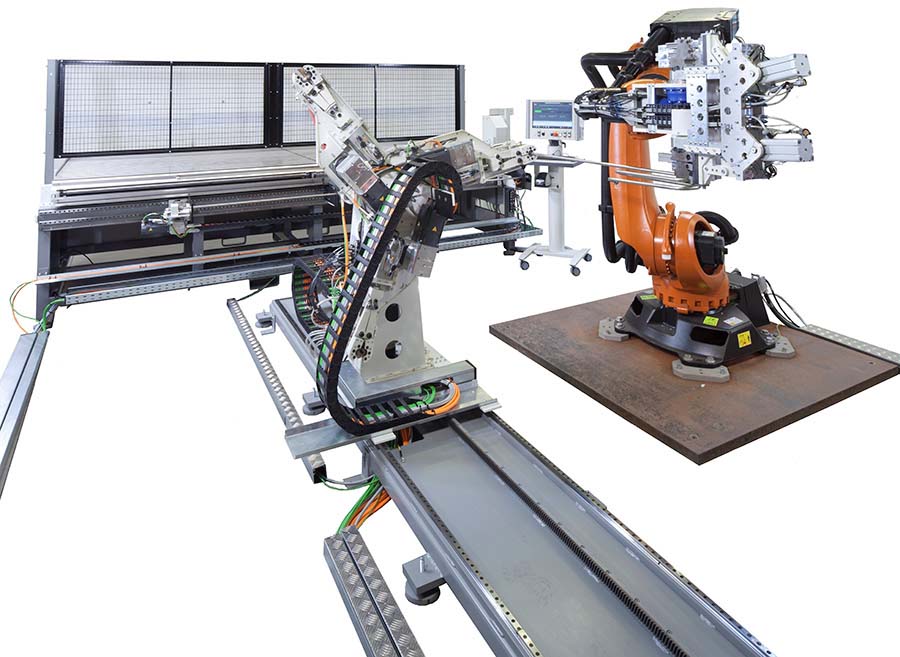

The transfluid bending cells with two robots bend long tubes at both ends. This way tubes can be supplied with forming, hoses or connection systems; with this the preparation and cleaning of the tubes becomes a lot easier. These benefits can be enjoyed both when bending with one or two robots.

With a set-up with two robots it is possible to process tubes of up to 6,000 mm. The two robots work in a synchronized way. Additional equipment like clamping or support devices also synchronizes. The robots could recognize the component with a code, generate the bending sequence and they can also choose between different radii and diameters. It is possible to work with a total of six different tube diameters or radii without having to change the dies.

The whole system is operated by a bending machine control unit. The benefit is that it is possible to work both with x, y and z coordinates, but also with lengths and bending angles, just like a standard bending machine.

It is not necessary to have special knowledge of robot programming. In order to keep the set-up times as short as possible, the robots have pre-programmed tool settings, including axes for the set up position. This keeps the set-up time short.

transfluid has now designed the next step of its tube bending robots. The online connection to CAD systems reduces the set-up time a lot. Another important aspect is to simplify the software connection for more convenience for the customer.

The latest generation of machines can process isometrics data online. There are also positions stored in the control system, where the piece is picked up and dropped off. A complete new complex bending geometry can be programmed quickly, in max. 30 minutes. This including the set-up of the bending tools.

The transfluid bending cells with two robots bend long tubes at both ends. This way tubes can be supplied with forming, hoses or connection systems; with this the preparation and cleaning of the tubes becomes a lot easier. These benefits can be enjoyed both when bending with one or two robots.

With a set-up with two robots it is possible to process tubes of up to 6,000 mm. The two robots work in a synchronized way. Additional equipment like clamping or support devices also synchronizes. The robots could recognize the component with a code, generate the bending sequence and they can also choose between different radii and diameters. It is possible to work with a total of six different tube diameters or radii without having to change the dies.

The whole system is operated by a bending machine control unit. The benefit is that it is possible to work both with x, y and z coordinates, but also with lengths and bending angles, just like a standard bending machine.

It is not necessary to have special knowledge of robot programming. In order to keep the set-up times as short as possible, the robots have pre-programmed tool settings, including axes for the set up position. This keeps the set-up time short.

Contact partner

Fabian Funke

Technische Beratung und Vertrieb

Video

By clicking on the "play" button you give your consent to an external video platform (YOUTUBE) setting cookies on the device you are using.

More information

Product images

Further information